1. Cervantes-Pahm SK, Stein HH. Effect of dietary soybean oil and soybean protein concentration on the concentration of digestible amino acids in soybean products fed to growing pigs. J Anim Sci 2008; 86:1841–9.

https://doi.org/10.2527/jas.2007-0721

2. Goebel KP, Stein HH. Ileal digestibility of amino acids in conventional and low-Kunitz soybean products fed to weanling pigs. Asian-Australas J Anim Sci 2011; 24:88–95.

https://doi.org/10.5713/ajas.2011.90583

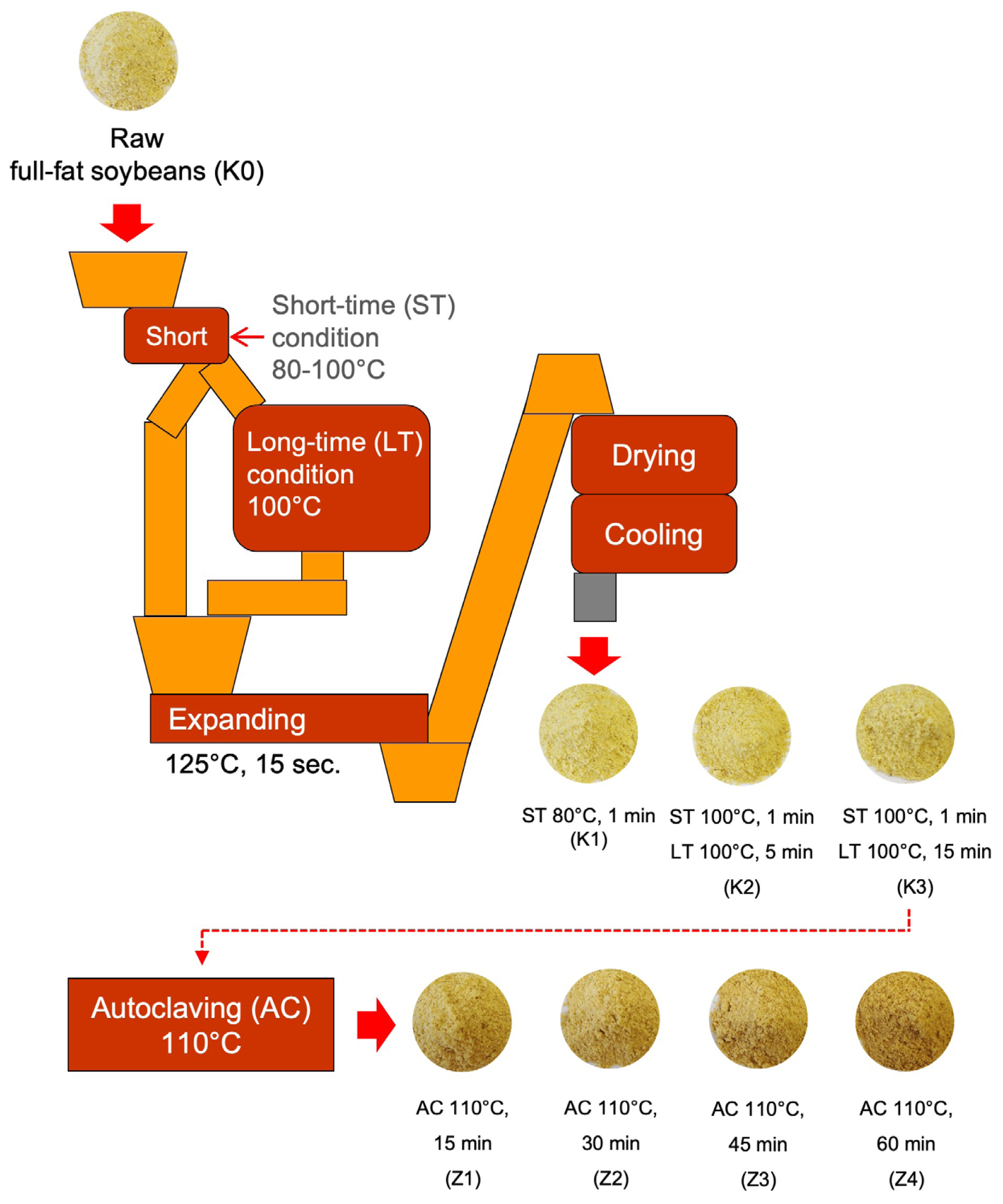

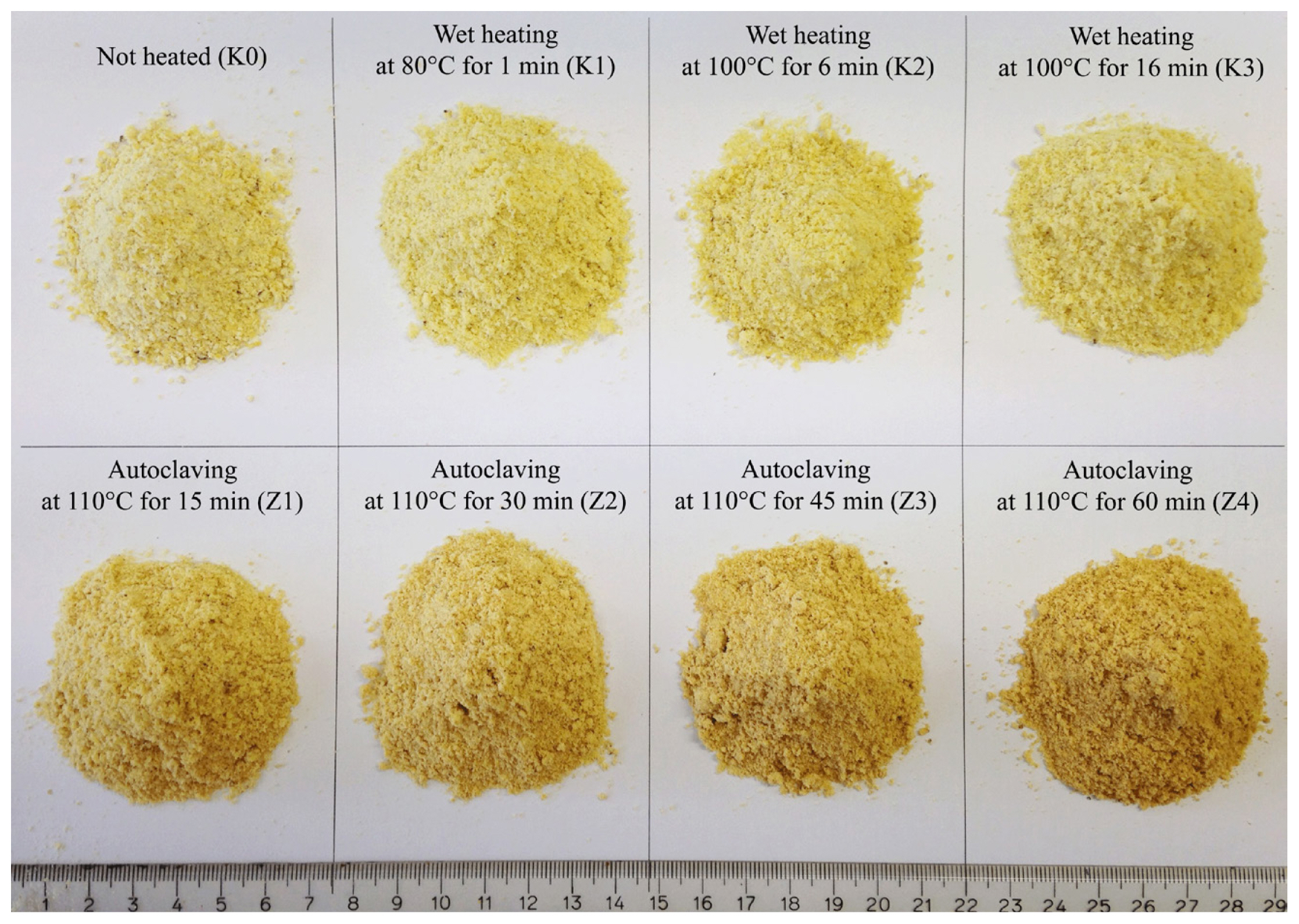

3. Kaewtapee C, Eklund M, Wiltafsky M, Piepho HP, Mosenthin R, Rosenfelder P. Influence of wet heating and autoclaving on chemical composition and standardized ileal crude protein and amino acid digestibility in full-fat soybeans for pigs. J Anim Sci 2017; 95:779–88.

https://doi.org/10.2527/jas.2016.0932

4. Pahm AA, Pedersen C, Stein HH. Application of the reactive lysine procedure to estimate lysine digestibility in distillers dried grains with solubles fed to growing pigs. J Agric Food Chem 2008; 56:9441–6.

https://doi.org/10.1021/jf801618g

5. Batal AB, Douglas MW, Engram AE, Parsons CM. Protein dispersibility index as an indicator of adequately processed soybean meal. Poult Sci 2000; 79:1592–6.

https://doi.org/10.1093/ps/79.11.1592

6. Fontaine J, Zimmer U, Moughan PJ, Rutherfurd SM. Effect of heat damage in an autoclave on the reactive lysine contents of soy products and corn distillers dried grains with solubles. Use of the results to check on lysine damage in common qualities of these ingredients. J Agric Food Chem 2007; 55:10737–43.

https://doi.org/10.1021/jf071747c

7. González-Vega JC, Kim BG, Htoo JK, Lemme A, Stein HH. Amino acid digestibility in heated soybean meal fed to growing pigs. J Anim Sci 2011; 89:3617–25.

https://doi.org/10.2527/jas.2010-3465

8. VDLUFA. Handbuch der Landwirtschaftlichen Versuchs-und Untersuchungsmethodik (VDLUFA-Methodenbuch), III Die chemische Untersuchung von Futtermitteln. Darmstadt, Germany: VDLUFA-Verlag; 2007.

9. Haese E, Titze N, Rodehutscord M. In situ ruminal disappearance of crude protein and phytate from differently processed rapeseed meals in dairy cows. J Sci Food Agric 2021; 102:2805–12.

https://doi.org/10.1002/jsfa.11621

10. AOAC. Official methods of analysis of AOAC. 18th edGaithersburg, MD, USA: AOAC International; 2000.

12. AACC (American Association of Cereal Chemists). Approved method for trypsin inhibitor, method 71-10. 9th edSt. Paull, MN, USA: AACC; 1995.

14. ISO 5506-1988. Soya bean products - Determination of urease activity. International Organization for Standardization. Geneva, Switzerland: ISO; 1988.

15. AOCS (American Oil Chemists’ Society). Protein dispersibility index (Official method ba 10-65). Champaign, IL, USA: AOCS; 1980.

17. Herkelman KL, Cromwell GL, Stahly TS, Pfeiffer TW, Knabe DA. Apparent digestibility of amino acids in raw and heated conventional and low-trypsin-inhibitor soybeans for pigs. J Anim Sci 1992; 70:818–26.

https://doi.org/10.2527/1992.703818x

19. Yen JT, Jensen AH, Simon J. Effect of dietary raw soybean and soybean trypsin inhibitor on trypsin and chymotrypsin activities in the pancreas and in small intestinal juice of growing swine. J Nutr 1977; 107:156–65.

https://doi.org/10.1093/jn/107.1.156

20. Kaankuka FG, Balogun TF, Tegbe TSB. Effects of duration of cooking of full-fat soya beans on proximate analysis, levels of antinutritional factors, and digestibility by weanling pigs. Anim feed Sci Technol 1996; 62:229–37.

https://doi.org/10.1016/S0377-8401(96)00952-2

21. Qin G, Elst ERT, Bosch MW, Poel AFB. Thermal processing of whole soya beans: Studies on the inactivation of antinutritional factors and effects on ileal digestibility in piglets. Anim Feed Sci Technol 1996; 57:313–24.

https://doi.org/10.1016/0377-8401(95)00863-2

22. Palacios MF, Easter RA, Soltwedel KT, et al. Effect of soybean variety and processing on growth performance of young chicks and pigs. J Anim Sci 2004; 82:1108–14.

https://doi.org/10.2527/2004.8241108x

25. Bruce KJ, Karr-Lilienthal LK, Zinn KE, et al. Evaluation of the inclusion of soybean oil and soybean processing by-products to soybean meal on nutrient composition and digestibility in swine and poultry. J Anim Sci 2006; 84:1403–14.

https://doi.org/10.2527/2006.8461403x

27. Parsons CM, Hashimoto K, Wedekind KJ, Baker DH. Soybean protein solubility in potassium hydroxide: an in vitro test of in vivo protein quality. J Anim Sci 1991; 69:2918–24.

https://doi.org/10.2527/1991.6972918x

29. Ames JM. The Maillard reaction. Hudson , editorBiochemistry of food proteins. London, UK: Elsevier Applied Science; 1992. p. 99–153.

31. Pastuszewska B, Jabłecki G, Buraczewska L, et al. The protein value of differently processed rapeseed solvent meal and cake assessed by in vitro methods and in tests with rats. Anim Feed Sci Technol 2003; 106:175–88.

https://doi.org/10.1016/S0377-8401(03)00005-1

32. Eklund M, Sauer N, Schöne F, et al. Effect of processing of rapeseed under defined conditions in a pilot plant on chemical composition and standardized ileal amino acid digestibility in rapeseed meal for pigs. J Anim Sci 2015; 93:2813–25.

https://doi.org/10.2527/jas.2014-8210

33. Almeida FN, Htoo JK, Thomson J, Stein HH. Effects of heat treatment on the apparent and standardized ileal digestibility of amino acids in canola meal fed to growing pigs. Anim Feed Sci Technol 2014; 187:44–52.

https://doi.org/10.1016/j.anifeedsci.2013.09.009

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print