|

|

| Anim Biosci > Volume 34(6); 2021 > Article |

|

Abstract

Objective

Methods

Results

ACKNOWLEDGMENTS

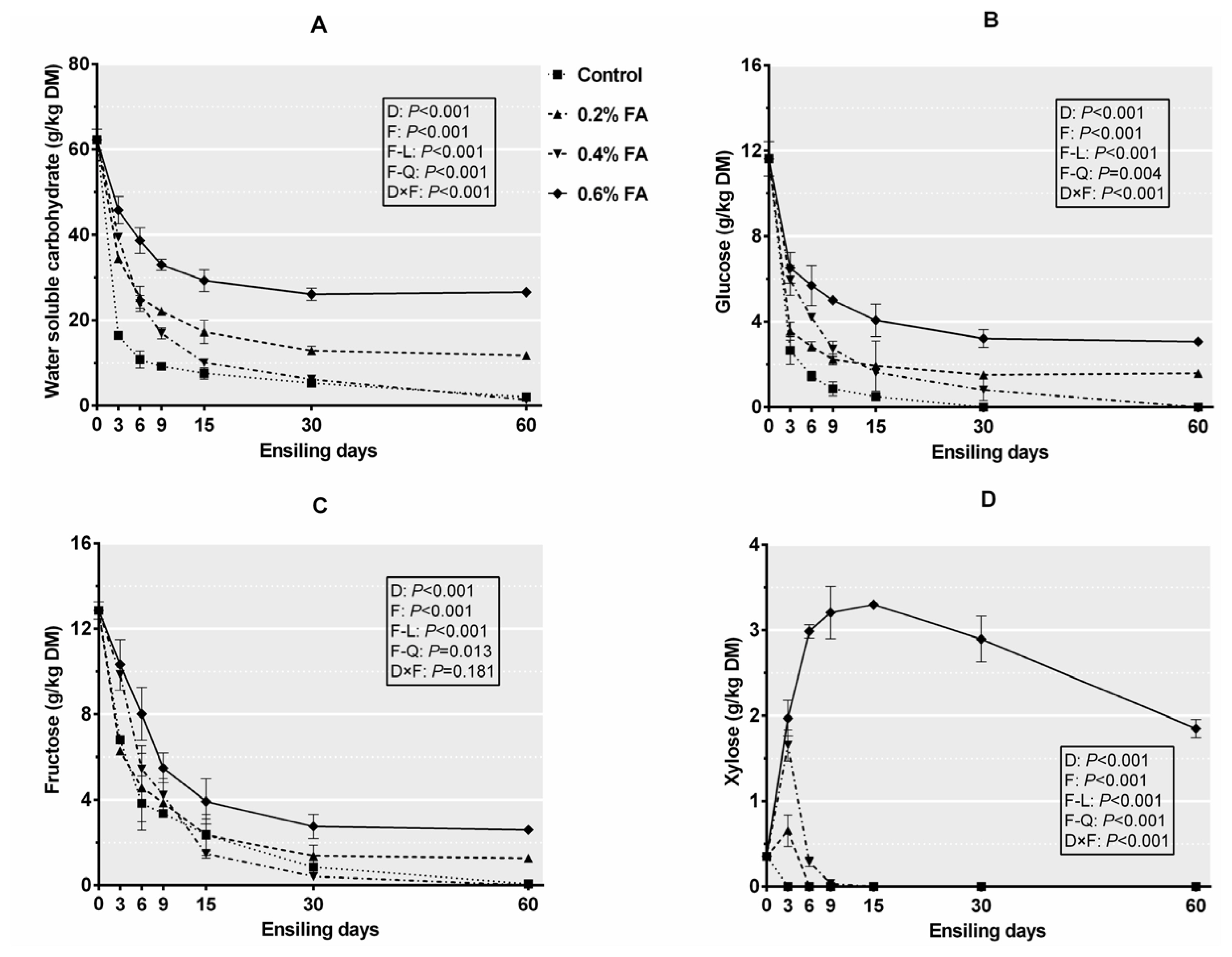

Figure┬Ā1

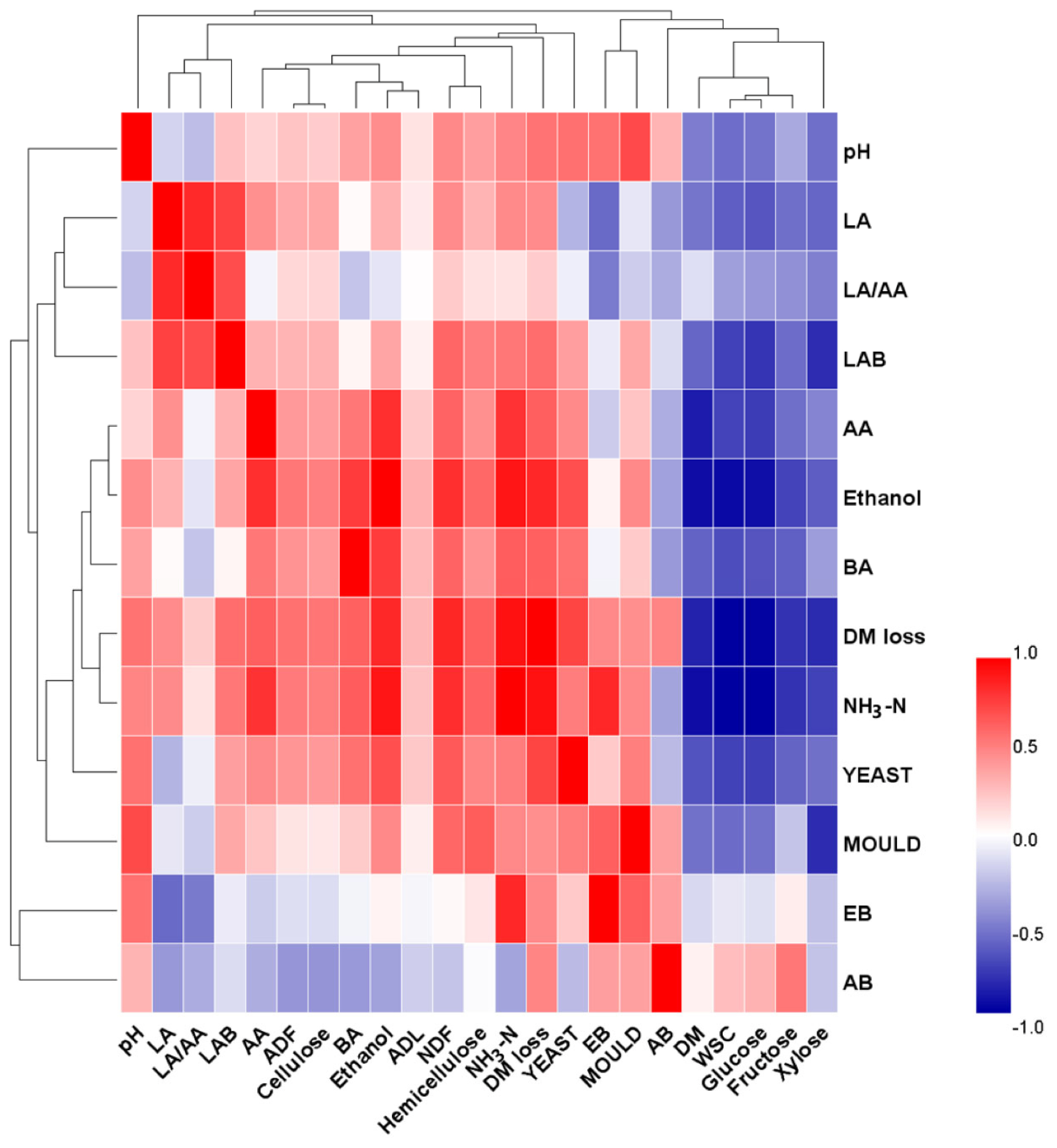

Figure┬Ā2

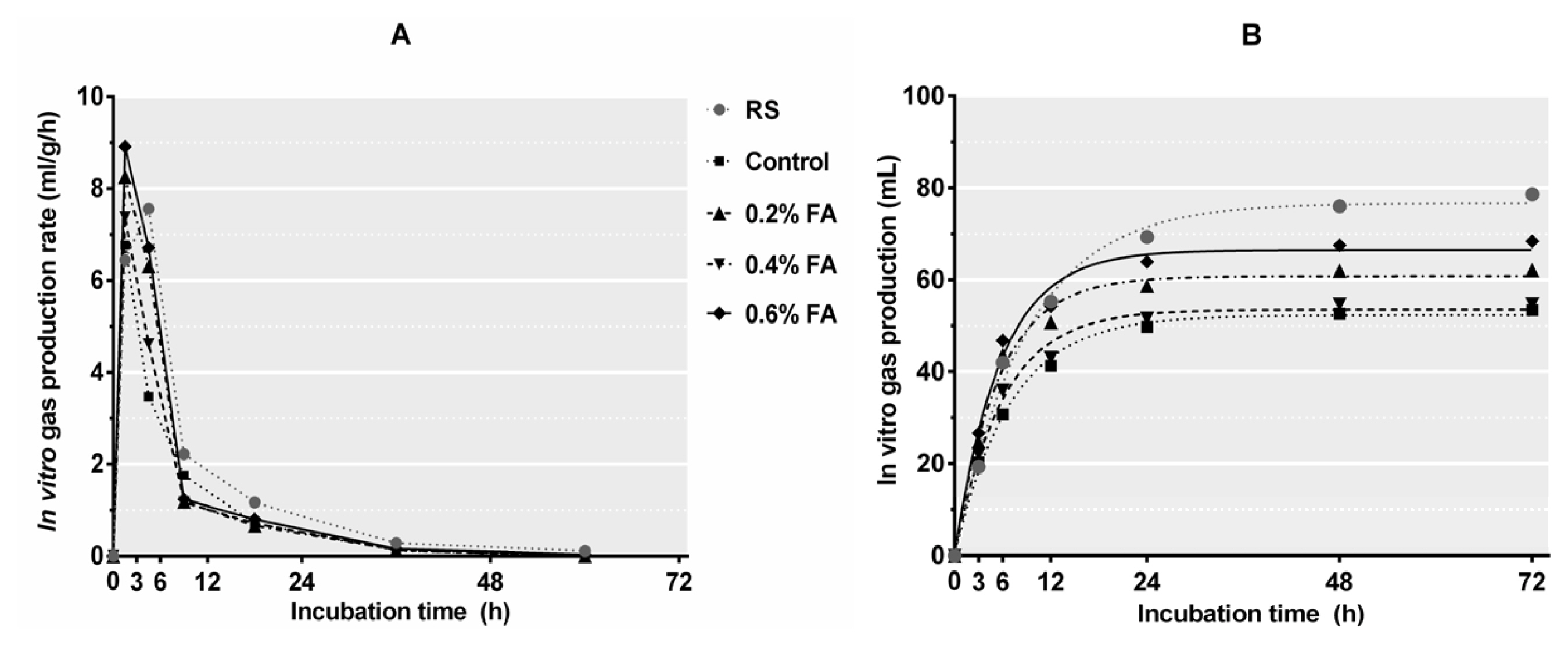

Figure┬Ā3

Figure┬Ā4

Table┬Ā1

DM, dry matter; FW, fresh weight; CP, crude protein; WSC, water soluble carbohydrate; NDF, neutral detergent fibre; ADF, acid detergent fibre; ADL, acid detergent lignin; BC, buffering capacity; mEq, milligram equivalent; FC, fermentation coefficient; cfu, colony-forming units; LAB, lactic acid bacteria; EB, enterobacteria; AB, aerobic bacteria.

Table┬Ā2

| Items | Treatments1) | Ensiling days | Mean | SEM | p-value2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||||||||

| 3 | 6 | 9 | 15 | 30 | 60 | D | F | F-L | F-Q | D├ŚF | ||||

| pH | Control | 5.44Aa | 5.23Aab | 4.65b | 4.72ABb | 4.68ABb | 4.78ABb | 4.92A | 0.052 | 0.007 | <0.001 | <0.001 | 0.085 | <0.001 |

| 0.2% FA | 5.06Ba | 5.03Aa | 4.49b | 4.30Cb | 4.19Bb | 4.28Bb | 4.56B | |||||||

| 0.4% FA | 4.32Cc | 4.64Bbc | 4.52bc | 4.80Aabc | 5.18Aab | 5.43Aa | 4.82A | |||||||

| 0.6% FA | 4.03Ca | 4.24Ca | 4.13a | 4.33BCa | 4.28ABa | 4.30Ba | 4.27C | |||||||

| Lactic acid (% DM) | Control | 1.23Ac | 1.92Ac | 2.51Aabc | 3.67Aab | 3.92Aa | 2.28Bbc | 2.59A | 0.210 | <0.001 | <0.001 | <0.001 | 0.020 | <0.001 |

| 0.2% FA | 0.49Bc | 1.18Bbc | 1.81ABbc | 3.49Aab | 5.78Aa | 5.54Aa | 3.05A | |||||||

| 0.4% FA | 0.05Bc | 0.11Cc | 0.27Bbc | 0.63Bab | 0.81Bab | 1.14Ca | 0.50B | |||||||

| 0.6% FA | 0.04Bc | 0.07Cc | 0.16Bbc | 0.11Bbc | 0.42Bab | 0.71Ca | 0.25B | |||||||

| Acetic acid (% DM) | Control | 0.69Ae | 0.83Ade | 1.01Ad | 1.30Ac | 2.24Ab | 2.58Aa | 1.44A | 0.072 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 0.30Bc | 0.38Bbc | 0.40Babc | 0.52Babc | 0.60Bab | 0.63Ba | 0.47B | |||||||

| 0.4% FA | 0.23Bd | 0.19Cd | 0.25Ccd | 0.37Bbc | 0.46BCb | 0.74Ba | 0.37C | |||||||

| 0.6% FA | 0.23Bc | 0.20Cc | 0.20Cc | 0.25Bbc | 0.44Ca | 0.38Cab | 0.28D | |||||||

| Butyric acid (% DM) | Control | NDb | NDb | NDb | 0.04b | 0.17Aa | 0.21Aa | 0.07A | 0.010 | <0.001 | <0.001 | <0.001 | 0.028 | <0.001 |

| 0.2% FA | ND | ND | ND | ND | NDB | NDB | 0.00B | |||||||

| 0.4% FA | NDb | NDb | 0.03b | 0.04b | 0.22Aa | 0.27Aa | 0.09A | |||||||

| 0.6% FA | ND | ND | ND | ND | NDB | NDB | 0.00B | |||||||

| LA/AA | Control | 1.77Aab | 2.31Aab | 2.46ABa | 2.84ABa | 1.75Bab | 0.88Cc | 2.00B | 0.032 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 1.62Ac | 3.32Abc | 4.43Aabc | 7.44Aabc | 9.57Aa | 8.80Aab | 5.86A | |||||||

| 0.4% FA | 0.20B | 0.57B | 1.08B | 2.01AB | 1.72B | 1.55BC | 1.19BC | |||||||

| 0.6% FA | 0.17Bb | 0.38Bb | 0.80Bb | 0.45Bb | 1.02Bab | 1.90Ba | 0.78C | |||||||

SEM, standard error of means; DM, dry matter; LA/AA, ratio of lactic acid to acetic acid; ND, not detected.

1) Control, no additive; 0.2% FA, 0.2% formic acid; 0.4% FA, 0.4% formic acid; 0.6% FA, 0.6% formic acid;

Table┬Ā3

| Items (log10 cfu/g FW) | Treatments1) | Ensiling days | Mean | SEM | p-value2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||||||||

| 3 | 6 | 9 | 15 | 30 | 60 | D | F | F-L | F-Q | D├ŚF | ||||

| LAB | Control | 5.64Aabc | 6.23Aa | 5.91Aab | 5.53Bbc | 5.20Bcd | 4.75Bd | 5.54B | 0.158 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 4.15Bd | 5.68Bc | 6.09Abc | 6.72Aa | 7.05Aa | 6.13Ab | 5.97A | |||||||

| 0.4% FA | 3.38Cc | 3.43Cc | 3.69Bbc | 4.25Cb | 5.10Ba | 4.93Ba | 4.13C | |||||||

| 0.6% FA | 2.53Dd | 2.74Dcd | 3.13Bbc | 3.33Db | 3.98Ca | 2.90Cbcd | 3.10D | |||||||

| EB | Control | 8.43Aa | 7.70Aab | 7.11Ab | 6.86Ab | 3.89Cc | 3.94Cc | 6.32A | 0.255 | <0.001 | <0.001 | <0.001 | 0.375 | <0.001 |

| 0.2% FA | 7.92Aa | 7.24Ab | 6.81Ac | 6.59Ac | NDDd | NDDd | 4.76B | |||||||

| 0.4% FA | 5.95Bb | 6.10Bab | 6.35Bab | 6.71Aab | 6.99Aa | 6.53Aab | 6.44A | |||||||

| 0.6% FA | 3.61Cc | 3.83Cbc | 3.99Cb | 5.62Ba | 5.69Ba | 5.88Ba | 4.77B | |||||||

| Yeasts | Control | 5.25Aa | 4.86Aab | 4.82Aab | 4.75Aab | 4.23Ab | 4.59Aab | 4.75A | 0.063 | <0.001 | <0.001 | <0.001 | 0.468 | 0.001 |

| 0.2% FA | 3.94Acd | 4.52Aab | 4.76Aa | 4.02Abcd | 4.38Babc | 3.81Bd | 4.24BC | |||||||

| 0.4% FA | 3.89Bc | 3.91Bc | 3.94Bc | 4.56Abc | 5.39Aa | 5.07Aab | 4.46AB | |||||||

| 0.6% FA | 3.78Bb | 3.82Bb | 3.82Bb | 4.09Aab | 4.23Ba | 3.91Bb | 3.94C | |||||||

| Moulds | Control | 4.92A | 4.80A | 4.31A | 3.73A | 3.38A | 3.45A | 4.10A | 0.211 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 4.05Ba | 4.12ABa | 3.89Aa | 2.56Bb | NDBc | NDBc | 2.44C | |||||||

| 0.4% FA | 2.48Cc | 3.55Bab | 4.06Aab | 4.32Aa | 4.42Aa | 3.29Abc | 3.69B | |||||||

| 0.6% FA | NDD | NDC | NDB | NDC | NDB | NDB | 0.00D | |||||||

| AB | Control | 7.03Aa | 6.41Ab | NDBc | NDc | NDc | NDc | 2.24A | 0.269 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 4.57Cb | 5.02Ba | NDBc | NDc | NDc | NDc | 1.60B | |||||||

| 0.4% FA | 5.31BCa | 4.50Cb | 4.64Ab | NDc | NDc | NDc | 2.41A | |||||||

| 0.6% FA | 3.68Da | NDDb | NDBb | NDb | NDb | NDb | 0.61C | |||||||

cfu, colony-forming units; FW, fresh weight; SEM, standard error of means; LAB, lactic acid bacteria; EB, enterobacteria; ND, not detected; AB, aerobic bacteria.

1) Control, no additive; 0.2% FA, 0.2% formic acid; 0.4% FA, 0.4% formic acid; 0.6% FA, 0.6% formic acid.

Table┬Ā4

| Items | Treatments1) | Ensiling days | Mean | SEM | p-value2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||||||||

| 3 | 6 | 9 | 15 | 30 | 60 | D | F | F-L | F-Q | D├ŚF | ||||

| DM (% FW) | Control | 35.2Ba | 32.7Bbc | 34.2Bab | 32.8Bbc | 32.0Bbc | 31.8Cc | 33.1C | 0.380 | <0.001 | <0.001 | <0.001 | <0.001 | 0.613 |

| 0.2% FA | 40.0A | 39.3A | 38.9A | 38.1A | 37.7A | 36.8A | 38.5B | |||||||

| 0.4% FA | 39.5Aab | 40.2Aa | 38.6Aabc | 36.9ABabc | 35.7ABbc | 34.5Bc | 37.6B | |||||||

| 0.6% FA | 40.7A | 40.6A | 40.8A | 41.0A | 39.2A | 38.6A | 40.1A | |||||||

| DM loss (% DM) | Control | 8.90Ac | 12.8Ab | 12.4Abc | 14.3Aab | 15.4Aab | 16.8Aa | 13.4A | 0.559 | <0.001 | <0.001 | <0.001 | 0.015 | 0.018 |

| 0.2% FA | 6.70Ab | 8.84ABb | 10.0ABab | 10.7Aa | 10.8ABa | 11.3Ba | 9.72B | |||||||

| 0.4% FA | 3.69Bd | 6.74ABcd | 8.73ABcd | 11.3Abc | 15.7Aab | 17.1Aa | 10.5B | |||||||

| 0.6% FA | 2.81Bc | 3.23Bab | 3.34Bab | 4.20Bab | 5.47Bab | 6.76Ca | 4.30C | |||||||

| NH3-N (% TN) | Control | 9.89Ac | 13.0Abc | 13.8Abc | 14.9Ab | 16.4Aab | 19.8Aa | 14.6A | 0.546 | <0.001 | <0.001 | <0.001 | 0.011 | <0.001 |

| 0.2% FA | 5.43Bb | 6.68Bb | 7.57Bab | 8.78ABa | 9.07Ca | 9.87Ba | 8.57B | |||||||

| 0.4% FA | 3.36Bd | 5.76Bcd | 7.44Bbc | 9.96ABb | 13.9Ba | 18.9Aa | 9.89B | |||||||

| 0.6% FA | 3.18Bc | 3.97Bc | 4.12Cbc | 5.12Babc | 6.39Dab | 7.03Ca | 4.97C | |||||||

| Ethanol (% DM) | Control | 0.82Ad | 1.23Ac | 1.39Abc | 1.63Ab | 2.04Aa | 2.14Aa | 1.54A | 0.065 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 0.42Bb | 0.62Bab | 0.70BCab | 0.77Ca | 0.73Ca | 0.61Bab | 0.64C | |||||||

| 0.4% FA | 0.38BCd | 0.60Bcd | 0.82Bbc | 1.09Bb | 1.59Ba | 1.76Aa | 1.04B | |||||||

| 0.6% FA | 0.32Cd | 0.39Bcd | 0.44Cbc | 0.52Cab | 0.59Ca | 0.54Bab | 0.47D | |||||||

SEM, standard error of means; DM, dry matter; FW, fresh weight; NH3-N, ammonia nitrogen; TN, total nitrogen.

1) Control, no additive; 0.2% FA, 0.2% formic acid; 0.4% FA, 0.4% formic acid; 0.6% FA, 0.6% formic acid.

Table┬Ā5

| Items | Treatments1) | Ensiling days | Mean | SEM | p-value2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||||||||

| 3 | 6 | 9 | 15 | 30 | 60 | D | F | F-L | F-Q | D├ŚF | ||||

| NDF (% DM) | Control | 63.2Ad | 66.1Ac | 68.0Ab | 68.3Ab | 69.2Ab | 71.1Aa | 67.7A | 0.496 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| 0.2% FA | 62.0ABb | 64.1Bab | 66.1ABa | 66.0ABa | 65.6Ba | 64.9Bab | 64.8B | |||||||

| 0.4% FA | 61.0Cd | 63.3Bcd | 64.9ABbcd | 66.5Aabc | 68.5Aab | 71.3Aa | 65.9AB | |||||||

| 0.6% FA | 59.8Ca | 58.6Cab | 58.4Cab | 58.7Bab | 58.4Cab | 57.9Cb | 58.6C | |||||||

| ADF (% DM) | Control | 39.0c | 40.4bc | 41.5ab | 41.9ab | 42.0ab | 42.9a | 41.3 | 0.292 | 0.005 | 0.058 | 0.010 | 0.694 | 0.268 |

| 0.2% FA | 38.2 | 39.1 | 40.0 | 40.7 | 41.0 | 41.1 | 40.0 | |||||||

| 0.4% FA | 37.5d | 38.9cd | 39.3bc | 40.0bc | 42.0ab | 43.4a | 40.2 | |||||||

| 0.6% FA | 38.0 | 38.3 | 38.9 | 39.6 | 39.6 | 39.8 | 39.0 | |||||||

| ADL (% DM) | Control | 5.33 | 5.47 | 5.42 | 5.55 | 5.58 | 5.87 | 5.54 | 0.061 | 0.544 | 0.423 | 0.250 | 0.649 | 0.916 |

| 0.2% FA | 5.22 | 5.35 | 5.23 | 5.31 | 5.29 | 5.35 | 5.29 | |||||||

| 0.4% FA | 5.15 | 5.27 | 5.29 | 5.39 | 5.57 | 5.97 | 5.44 | |||||||

| 0.6% FA | 5.11 | 5.18 | 5.22 | 5.33 | 5.29 | 5.36 | 5.25 | |||||||

| Cellulose (% DM) | Control | 33.7b | 34.9ab | 36.1a | 36.3a | 36.5a | 37.0a | 35.8 | 0.265 | 0.007 | 0.072 | 0.013 | 0.727 | 0.131 |

| 0.2% FA | 33.0b | 33.7ab | 34.8ab | 35.4a | 35.7a | 35.7a | 34.7 | |||||||

| 0.4% FA | 32.4b | 33.6ab | 34.0ab | 34.7ab | 36.4a | 37.5a | 34.7 | |||||||

| 0.6% FA | 32.9 | 33.1 | 33.7 | 34.3 | 34.3 | 34.4 | 33.8 | |||||||

| Hemicellulose (% DM) | Control | 24.2Ac | 25.7Abc | 26.5Aab | 26.4Aab | 27.2Aab | 28.2Aa | 26.4A | 0.399 | 0.730 | <0.001 | <0.001 | <0.001 | 0.139 |

| 0.2% FA | 23.8A | 25.1A | 26.1A | 25.3AB | 24.7B | 23.8B | 24.8B | |||||||

| 0.4% FA | 23.5Ac | 24.4Abc | 25.6Aab | 26.4Aab | 26.5Aab | 27.9Aa | 25.7A | |||||||

| 0.6% FA | 21.9Ba | 20.3Bab | 19.5Bab | 19.0Bab | 18.8Cab | 18.1Cb | 19.6C | |||||||

SEM, standard error of means; NDF, neutral detergent fibre; DM, dry matter; ADF, acid detergent fibre; ADL, acid detergent lignin.

1) Control, no additive; 0.2% FA, 0.2% formic acid; 0.4% FA, 0.4% formic acid; 0.6% FA, 0.6% formic acid.

Table┬Ā6

| Items | Treatments1) | SEM | p-value2) | |||||

|---|---|---|---|---|---|---|---|---|

|

|

|

|||||||

| Control | 0.2% FA | 0.4% FA | 0.6% FA | F | F-L | F-Q | ||

| CP (% DM) | 5.89B | 6.27A | 6.05AB | 6.35A | 0.044 | 0.009 | 0.009 | 0.617 |

| Ash (% DM) | 14.9A | 13.3B | 15.0A | 12.8B | 0.318 | 0.001 | 0.007 | 0.335 |

| Potential gas production, b (mL) | 52.3C | 60.8B | 53.5C | 66.5A | 1.473 | <0.001 | <0.001 | 0.034 |

| Gas production rate constant, c (mL/h) | 0.15 | 0.18 | 0.17 | 0.18 | 0.012 | 0.052 | 0.035 | 0.195 |

| In vitro dry matter degradability (%) | 53.5 | 52.5 | 51.0 | 53.6 | 1.221 | 0.279 | 0.801 | 0.106 |

| In vitro neutral detergent fibre degradability (%) | 51.4 | 49.5 | 50.7 | 49.0 | 2.430 | 0.852 | 0.755 | 0.787 |

| In vitro acid detergent fibre degradability (%) | 44.5 | 45.3 | 44.8 | 45.6 | 2.838 | 0.725 | 0.418 | 0.701 |

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Full text via PMC

Full text via PMC Download Citation

Download Citation Print

Print